Blog

Textile Industry - May 2021

In the textile industry, it is still common practice today to treat fabrics with wet chemicals, some of which are harmful to the environment.

This is true for the whole manufacturing range, from the yarns for T-shirts up to fabric for space suits designed to protect astronauts from radiation or cold.

Another environmental issue is the wide scope of colourants and pigments for dyeing fibres and textiles, as well as the consumption of vast amounts of water in the production of textiles.

With a plasma treatment, the surfaces of fibres and processed textiles can be modified in many different ways completely free of hazardous chemicals.

Hydrophobing via plasma treatment gives fabrics for functional garments hydrophobic properties.

A functionalisation of the fibre by plasma causes high adhesion, which can strengthen or even completely replace the effect of silanization.

Email us on info@2x3d.co.uk

#textiles #manufacturing #innovation #production #silicon #rubber #technology #medicaldevicemanufacturing #surfacetreatment #coatings #processimprovement #chemistry

Spectacles - April 2021

Hello 4 eyes. Old spectacle head.

All yesterdays insults and nowadays kind of funny.

Modern spectacles have become a loved fashion statement.

Their manufacturing maturity has seen great reductions in costs but also massive improvements in quality.

There is an untold number of variations on the theme but for sure all good production of these components would absolutely be compromised without the application of Plasma Surface Treatment to various aspects of assembly.

The lenses need coatings, these coatings need pre-treatment before and often after the different coatings.

The frame (regardless of the material), needs pre-treatment before painting.

Even the paint, needs pre-treatment before the logos are printed!

Email us on info@2x3d.co.uk

#innovation #medicaldevicemanufacturing #medicaldevice #engineering #production #surfacetreatment #silicon #contactlenses #sensors #technology #coatings

Your Car Keys! - March 2021

Can you think of any printed ink on any product that is jingled, jangled, knocked and rubbed anywhere near as much as the White print on your cars remote fob?

(If you haven't got one you still know what I mean).

Unless the substrate on those fobs are pre-treated to perfection then that Pad Printed Ink will not last more than a few years.

OK ........... this may not be the best example of the advantages Plasma treatment achieves as they will all wear, but you get the idea.

It's much better with Plasma Treatment.

Email us on info@2x3d.co.uk

#automotiveindustry #automotivedesign #innovation #medicaldevices #surfacetreatment #automotive #padprinting #screenprinting #engineering #automtion

Micro cleaning - February 2021

Plasma Surface Cleaning, or better described as micro cleaning.

Has found another application.

Archaeological finds.

Various metal and other material finds can be gentle and effectively micro cleaned by the application of a low pressure Plasma treatment.

Dig it?

Email us on info@2x3d.co.uk

#archaeology #preservation #innovation #engineering

Lip Gloss Applicator - February 2021

Lip Gloss Applicators - another secret German underground application for Plasma Surface Treatment.

Hundreds of different designs and made by the million, good quality lip gloss applicators are produced by 'Flocking'.

For a good 'Flocking' you need a good Plasma Treatment.

And that's where we come in!

We have lots of experience with this skill set so please ask for information now.

Don't wait for the weekend.

Email us on info@2x3d.co.uk

#flocking #surfacetreatment #plasma #innovation #medicaldevice #processimprovement #production #cosmetics #automotive #drugdelivery #beauty

Asbestos detection. - January 2021

Another day - another amazing application for Plasma.

We have perfected a novel method to effect fast detection of Asbestos partials within buildings.

Until now the analysis of samples is a specialist and time consuming task.

We take a used air filter and zap it with Plasma.

This removes the filter material leaving just the asbestos sample (if there is any!).

It's quick easy and is becoming a standard method.

Email us on info@2x3d.co.uk

#laboratory #processimprovement #agritech #chemistry #surfacetreatment #manufacturing #asbestosabatement #asbestosawareness #asbestoswatch #asbestosnews #asbestostesting #asbestossurvey #asbestosis

Airbags - January 2021

One of the greatest automotive safety innovations of all time.

Continually being developed with material, design and manufacturing improvements.

They continues to roll out with integrations as side protection, front & rear middle protection, rear window and sunroof protections and lately motorbike vest and helmet protections.

The internal material need to be bonded well and stay bonded for many years, these units must not fail.

Plasma surface treatment is used extensively within airbags to achieve these goals.

Email us on info@2x3d.co.uk

#manufacturing #innovation #processimprovement #rubber #silicon #manufacturingengineering #surfacetreatment #coatings #automotiveindustry #automotivetechnology #automotivesafety #engineering

AI203 Alumina Ceramics - January 2021

AI203 Alumina Ceramics (+ their Nanofibres), is a very useful material and used in many applications including abrasives, refractory, electrical isolation on PCB's, cutting tools, glass additive, Catalysis, Body armour, Medicines, Artificial joints, Spark plugs and others.

Our Plasma Surface Treatment can help with - Cleaning, Surface Activation, Polymerization and therefore bonding of these materials and their Substrates.

Can you add to this list?

Email us on info@2x3d.co.uk

#engineering #laboratory #silicon #innovation #processimprovement #manufacturingengineering #technology #manufacturing #medicaldevices #medicaldevicemanufacturing #surfacetreatment

Nylon is the oldest Synthetic Textile Fibre, it is made of Polyamide - January 2021

All textiles, both the raw fibres and finished fabrics (woven, knitted, crocheted) are usually treated with liquid chemicals.

We aim to update these processes by introduce our Plasma treatments.

Plasma Treatment in a Low-Pressure Plasma brings much better results than wet-chemical processes when it comes to reaching the gaps between yarns and the individual fibres.

Already today we have supplied many Plasma systems to the textile industry, these systems are used for:

-

Cleaning – Desizing – Hydrophiling – Activation before printing – Waterproofing – Oilproofing – Dirt repelling – Micro roughening of fibres – Finishing (Finishing is understood to include Bleaching, adding Antislip properties, Anti-fungal and anti-microbial properties, Flame Resistance, UV & Light fastness, Lint free and anti-static properties).

Many other applications are waiting to be discovered and rolled out in all sectors and with both the low and high volume producers.

We are here to help.

Email us on info@2x3d.co.uk

#manufacturing #printing #production #textiles #coatings #automotiveindustry #manufacturingengineering #medicaldevicemanufacturing #innovation #plasma #surfacetreatment

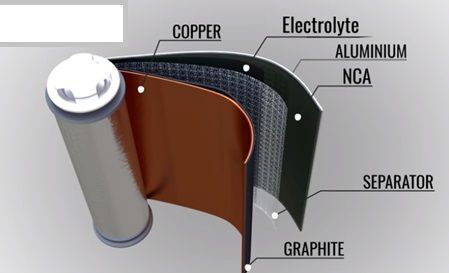

How To Improve Lithium Wickability - November 2020

How to improve Lithium Ion Battery Wickablility - with Plasma Treatment of course!

Many manufacturers of lithium ion batteries have found it necessary and often advantageous to incorporating surface treatment into their battery fabrication operations.

Plasma Surface Treatment offers real opportunities for in-line continuous improvements in surface wettability and cleanliness as a fast and dry surface treatment processes.

Some of the key benefits for this include:-

- Small footprint

- Elimination of chemical primers

- Low capital costs

- No VOCs or chemical effluent disposal costs

- Reductions in HSE requirements

- Reduction of training requirements

- No water supply costs

- Maintenance costs drastically reduces

- A Clean Green Process Improvement

Our technology enhances surface properties of separator and foil components of lithium ion batteries, resulting in increased hydrophilic and wick-ability characteristics Therefore improving the overall efficiency of the battery cells.

With the implementation of Plasma within the production process there is a considerable cost-reductions to be found in lithium-ion battery fabrication.

Email us on info@2x3d.co.uk

#production #manufacturingengineering #manufacturing #medicaldevicemanufacturing #medicaldevices #medicaldevice #automotiveindustry #bonding #innovation

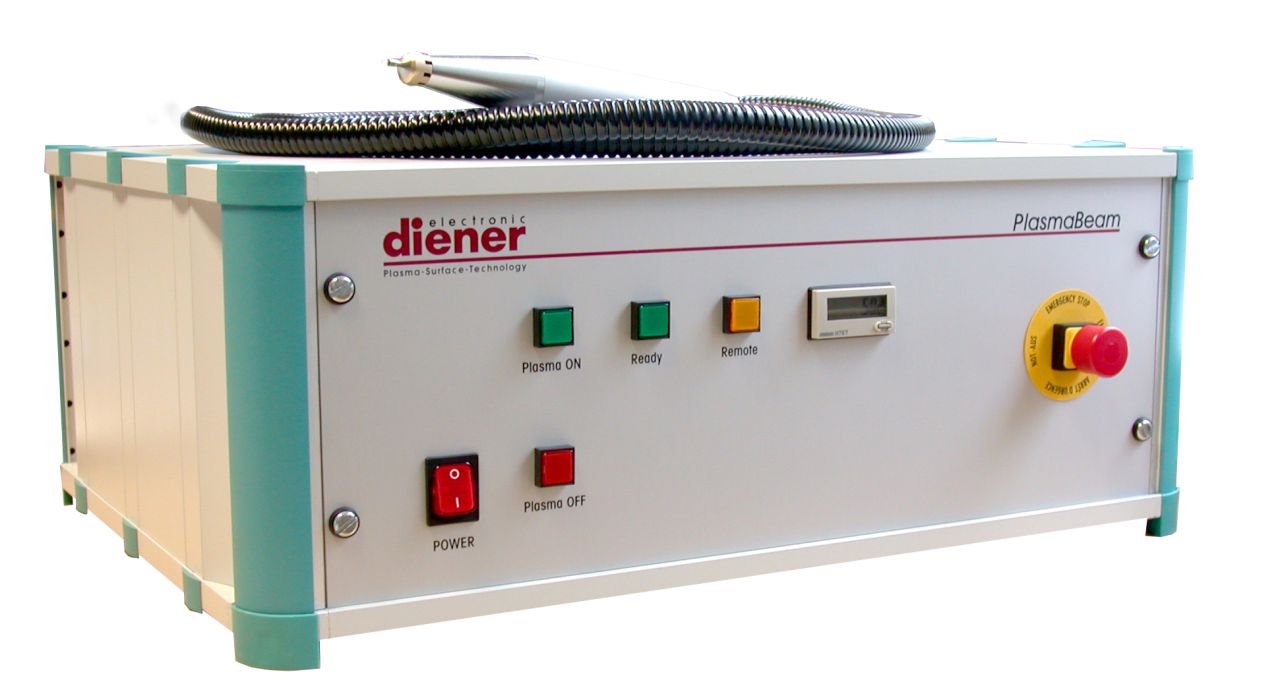

Plasma Beam Machine - November 2020

It is primarily used in the following sectors:-

Plastics technology

Automotive

Electrical engineering

Elastomer technology

Precision engineering

Small batch production

Micro-system technology

Medical engineering

Solar cell technology

Research and development

Semiconductor technology

Optics

Are you in these groups?

Do you know the technology?

We are here to help with your process improvements - Email us on info@2x3d.co.uk

#bonding #medicaldevice #medicaldevicemanufacturing #automotiveindustry #spaceindustry #plasma #silicon #surfaceengineering #processimprovement #printing #automotive #semiconductor #semiconductor #electronics #innovation #textiles #surfacetreatment #agriculture

Automotive Applications - November 2020

The Automotive industry is fast catching up with manufacturing processes in the medical device arena.

Both now demanding the highest possible standards that far exceed the demands in most other industries.

Surfaces must not just be clean but absolutely flawless (and in Medical devices – sterile).

The Pre-treatment processes in both Automotive and Medical technology must be very reliable, precisely reproducible and traceable.

Plasma Pre-treatment to improve adhesion of printing inks has been widely used in medical technology for some time, advances in application technology enables the process to roll out over an ever increasing number of applications and across all manufacturing sectors.

Our PlasmaBeam process allows for effective adhesion of hard/soft/hard material combinations, applying finishes to membranes (filter materials) and direct improvement of functionalization of most surfaces.

With the use of Plasma - all is guaranteed to be aseptic thanks to plasma sterilization effect.

Plasma - the Covid eliminator!

Email us on info@2x3d.co.uk

#automotiveindustry #manufacturingengineering #medicaldevicemanufacturing #medicaldevices #medicaldevice #automotive #bonding #silicon #engineering #innovation #printing #surfacetreatment #processimprovement #textiles #agriculture #plasma

New Developments In Plasma Technology - October 2020

New developments in Plasma Technology made by Diener Electronics have now made industrial-scale modification of plastic powders and granulates possible.

We have developed a low-pressure plasma system which can turn functional hydrophobic additives permanently hydrophilic, improving their product properties for a number of innovative applications.

For example - polyethylene is naturally hydrophobic, it cannot absorb moisture.

For this reason, the material is not suited for all types of applications.

The chemical bond between the plastic granulate and the additive is often missing.

The surface energy of this powder can be increased tenfold in a matter of several minutes by our low pressure rotary drum machines.

With these additives, plastic processing companies can for example develop rubbers with higher tear propagation strength or manufacture porous filter elements.

Up-scaling applications abound within the Automotive, Medical Device, Food, agriculture and FMCG sectors.

Email us on info@2x3d.co.uk

#manufacturing #production #medicaldevicemanufacturing #medicaldevices #medicaldevice #contactlenses #engineering #technology #coatings #nanomaterials #silicon #plasma #chemistry #automotiveindustry #rubber #laboratory #processimprovement #innovation

Plasticizers - September 2020

Do you use Plasticizers?

These are chemical agent added to plastic compositions that make the component softer and more flexible in use.

Nice in the end product but they restrict the applications of adhesives and inks during production.

So a quick application of some Plasma will temporarily remove these Plasticizers from the surface of the component.

Enabling your bonding and/or printing and/or coating to take place effectively.

The magic is that the component will recover, Plasticizer will leach back onto the surface, effectively fixing itself.

Clever eh?

Email us on info@2x3d.co.uk

#manufacturing #production #medicaldevicemanufacturing #medicaldevices #bonding #surfacetreatment #coatings #plasma #nanomaterials #silicon #medicaldevice #contactlenses #printing #sensors #rubber #processimprovement #textiles #automotiveindustry #technology

Parylene Coatings - September 2020

Parylene Coatings are often overlooked when coatings for Medical components are considered.

They do however offer a large number of benefits:-

They are completely conformal i.e. they adapt even to complex substrate contours such as sharp edges, bore holes or blind holes.

They are pinhole-free already from coat thicknesses of approx. 0.5 µm

They are chemically insoluble and resistant against a large number of chemicals.

They have very good barrier properties against moisture and chemicals, a high dielectric strength, dry lubricating properties (low coefficient of friction), they are hydrophobic: wetting angle for H2O between is 92° and 98°.

They are transparent between 90 and 96 % in the visible wavelength range (depending on type),

They are biocompatible:-

Parylenes of the types C and N can be separated which can be certified to USP Class VI, ISO 10993 and FDA.

Defo worth looking at.

Email us on info@2x3d.co.uk

#engineering #manufacturingengineering #medicaldevicemanufacturing #medicaldevices #bonding #surfacetreatment #coatings #plasma #nanomaterials #silicon #contactlenses #automotiveindustry #rubber #processimprovement #sensors #medicaldevice

Plasma in industry - July 2020

Plasma Treatment is used in almost all areas of industry.

That is because it is so easy to use it's very cost effective, safe and it can and is integrated within many high speed inline processes worldwide including the Automotive, FMCG, Space and aviation, Electronic Manufacturing, Packaging technology, Life Sciences, Textiles, Medical Device sectors and lately the new forms of energy storage and creation.

Out with the primitive manufacturing processes - in with the new.

Plasma Surface Treatments.

Email us on info@2x3d.co.uk

#bonding #plasma #adhesives #sensors #potting #nanomaterials #manufacturingprocesses #printingsolutions #productionengineering

Adhesive Bonding- June 2020

A massive, complex and very interesting sector of engineering that is forever evolving.

Engineering adhesives are continually replacing traditional fastenings when fabricating items.

The range of materials that can be bonded, the environmental conditions that they remain stable at and the structural performances are improving all of the time.

But ... they are only ever as good as the surfaces that they are applied to.

Our Plasma machines can improve the surfaces of any material such that a better bond can be achieved.

This improvement enables a wider range of potentially cheaper adhesives to be considered for the same applications.

Email us on info@2x3d.co.uk

#adhesives #materials #bonding #plastics #plastic #injectionmoulding #manufacturing #engineeringsolutions #coatings #coating #rubber #sealing #nanotechnology #sensors #plasma #surfacetreatment #composites #textiles

Oxygen Plasma - June 2020

What is an Oxygen Plasma?

Oxygen plasma refers to any Plasma treatment performed while introducing oxygen into the plasma chamber.

Oxygen is often used to clean surfaces prior to bonding, printing and coating.

Oxygen(O2) is the most common gas used in plasma cleaning technology due to its low cost and wide availability.

All systems available from Diener Electronic will work with oxygen gas.

An oxygen generator can be purchased and set up right in your facility (no bottles!).

Oxygen gas is commonly used to clean non-metal materials such as glass, plastics, and Teflon.

O2 plasma will clean the surface of a plastic sample and increase its wettability ready for the following processes.

As the O2 is asked to work in a low pressure environment there is only a minimal volume of gas used each cycle giving an extremely cost efficient process.

And the colours are great.

Email us on info@2x3d.co.uk

#plasma #bonding #plasmacleaning #medicaldevices #materials #adhesion #coating #nanodevices #sterilization #coatings #plastics #sensors #surfacetreatment #textiles

Automation - June 2020

Do you need to automate?

Run your finger left to right, one row at a time over the squares of a chess board at a constant speed and without crossing over the lines.

I can do that – can you?

Now do it again, faster.

And again – even faster.

Now do it 24/7 without going to the toilet.

Yes, you need to automate.

Hand held Plasma treatment units work but by human nature they will produce an inherently patchy Surface Treatment Performance.

And that is why we do not supply them.

Email us on info@2x3d.co.uk

#engineeringsolutions #plastics #surfacetreatment #coatings #adhesives #coating #plasma #rubber #materials #bonding #automationsolutions #industrialautomation #automationengineering #factoryautomation #plasticsindustry #automation #bespoke

Hydrogen Peroxide - June 2020

WHAT IS HYDROGEN PEROXIDE STERILIZATION?

Hydrogen peroxide sterilization is a low temperature effectively dry sterilization process involving a low pressure Plasma chamber - commonly used to sterilize heat-sensitive devices.

A hydrogen peroxide sterilization cycle typically requires less time than alternative forms of sterilization, such as ethylene oxide sterilization.

The process involves H2O2 vapor filling a loaded sterilizer chamber, contacting and sterilizing all 3D of the exposed device surfaces.

Once the sterilization cycle has completed, the vapor is vacuumed from the chamber and converted to water and oxygen.

A very green and thoroughly modern process overall, we are building machines for the reuse of previous single use items such as face masks but the technology could and should be much further utilised.h processing on desktop units right up to continuous Roll to Roll textile applications.

What do you need?

Email us on info@2x3d.co.uk

#engineeringsolutions #plastics #injectionmoulding #plastic #rubber #adhesives #coatings #coating #plasma #surfacetreatment #sealing #materials #bonding #sterilisation #medicaldevice #nanotechnology

Innovative Nano-Coatings - June 2020

We are reducing our customers carbon footprint with innovative nano-coatings.

Our technology replaces wet chemical coating processes which are often harmful to the environment and require far more energy than plasma nano-coatings.

Our ultra-thin coatings add permanent water repellent (Hydrophobic) and oil repellent (Oleophobic) properties to any solid surface without changing its colour and without affecting the performance of the component.

Often outperforming not only other nano-coating barriers commercially available, but also other types of conformal coating like acrylic, epoxy, silicone or even Parylene.

Available from batch processing on desktop units right up to continuous Roll to Roll textile applications.

What do you need?

Email us on info@2x3d.co.uk

#coatings #coating #adhesives #rubber #plastics #engineeringsolutions #materials #plasma #sealing #bonding #nano #hydrophilic #hydrophobic

Glass Printing Made Easy - June 2020

Glass is well known for being difficult to print on.

Remember the old pint glasses with print that fades?

There are some really good inks out there that will stay on to a certain extent for a certain amount of time but give the ink some stick (dishwasher or scratching) and it will come off.

Often the inks won't last well enough to give a printed product a good quality lifetime.

Wet chemical surfacants can be used to a certain extent, but they are just nasty, expensive and hazardous to the environment.

So use some Plasma - just electricity and voila! you have it - a pre-treated surface for the ink to grab hold off.

Cheap as can be.

Email us on info@2x3d.co.uk

Did someone mention ventilators? - April 2020

Respiratory masks - generally made from Silicon.

These product groups require a Plasma surface treatment before bonding the inner & outer shells.

They also require a Hydrophobic coating to function well.

We have the knowledge in-house and can supply the machinery quickly.

Awaiting your contact.

Email us on info@2x3d.co.uk

#surfacetreatment #coating #plasma #sealing #manufacturingprocesses #coatings #manufacturing #cpap #materials #bonding #surface #coatingstechnology #ventilators #coronavirus #masks

Production Performance.

- April 2020

Do you supply products that cannot fail, no matter what life throws at them?

Bonding dissimilar materials in Aircraft, Space Vehicles, Military, Motor Sport, Automotive or Medical Devices.

Plasma Pre-Treatments cannot be ignored.

The elimination of human caused inaccurateness that come with the manual acts of wet chemical wiping or abrasion operations by our green Plasma processing is a true step process improvement.

Forward with you.

Email us on info@2x3d.co.uk

#plasma #bonding #sealing #polymers #materials #composites #compositematerials #manufacturingprocesses #coating #surfacetreatment #coatings #aerospace #filters #nano #sensors #batteries #battery #solar #nanotechnology #lightweighting #automotive #automotiveindustry #electricvehicles

De-smearing Capabilities

- March 2020

When circuit boards are manufactured, layers of copper are often sandwiched between layers of polyimide or epoxy When these circuit boards are then drilled for wire bonding or IC chip installation, the polyimide or epoxy will smear on the copper which can create poor electrical connections A clean and smear-free hole is essential to reliably solder wire, IC chips, or other conductive material to the hole. Plasma cleaning cleans the residue left behind on the copper. It also etches away at the polyimide or epoxy material to allow multi-surface bonding to the solder or other conductive materials The process is significantly more accurate than traditional wet chemical cleaning methods. Our plasma products prevent the use of environmentally hazardous waste chemicals and creates no hazardous waste products This is safer for not only our environment but for staff as well. Plasma cleaning is often used in high grade and military applications No reason you can't have it too!

Email us on info@2x3d.co.uk

#materials #plasma #polymers #manufacturingprocesses #bonding #composites #compositematerials #surface #sealing #coating #coatings #aerospace #sensors #surfacetreatment #nanotechnology #batteries #stents #parylene #coatingstechnology #nano

Improving Lithiun Ion Batteries!

- December 2019

Improving Lithium Ion Battery Manufacturing with Plasma Treatment.

Manufacturers of lithium ion batteries have found significant benefits to incorporating Plasma Surface Treatment into their fabrication operations.

This cost effective and safe process offers real opportunities for in-line continuous improvements in surface wettability and cleanliness as it is a dry surface treatment processes.

Some of the key benefits include:

-

Continuous, roll-to-roll process available

Significantly lower production floor footprints

Elimination of chemical primers with their associated hidden costs

No VOCs or chemical effluent disposal costs

No water supply costs – a big green thumbs up for that one!

Our technology enhances surface properties of the separator and foil components of lithium ion batteries resulting in increased hydrophilicity, wickability and electrolyte retention improving the efficiency of the battery cells.

Plasma cleaning of the internal components will improve all bonding's and enhance overall battery performance.

Email us on info@2x3d.co.uk

#manufacturingprocesses #compositematerials #sealing #filters #composites #coating #material #polymers #materials #coatings #nanotechnology #batteries #EV #automotiveindustry

Etching Upgrade!

- October 2019

Conventional Etching methods are based on the chemical reaction of etching liquids (acids, dyes, organic solvents) with surface materials.

Not only are they expensive but pretty much all of these solvents are harmful to the environment, animals and us humans!

Etching without any of these harmful liquid solvents can be very satisfactorily completed within our low pressure plasma systems.

These processes are designated plasma etching, dry etching or chemically dry etching.

Generally any substrate material can be etched by a dry Plasma etching method.

I bet you can see the advantages!! info@2x3d.co.uk

#plasma #manufacturingprocesses #material #sealing #materials #surface #composites #coating #manufacturing #automotiveindustry #sensors #coatings #nanotechnology

Are finger print marks a problem?

- September 12th 2019

By Plasma polymerisation, coatings with an extremely low surface energy of less than 15 mN/m can be produced onto your products.

Such a coating avoids almost any adherence of particles. Also grease and minerals which are essential for fingerprints do not like to adhere.

By this method visible fingerprints which look very unattractive on high-polish surfaces can be avoided.

It's all easy when you know how!

info@2x3d.co.uk

www.2x3d.co.uk

info@2x3d.co.uk

#plasma #manufacturingprocesses #coating #sealing #coatings #surface #material #materials #automotiveindustry #nanotechnology

Asbestos Analysis via Plasma - August 2019

As Asbestos fibres are considered to be carcinogenic it is frequently desired to analyse if a room atmosphere is containing Asbestos.

For analysing the atmosphere is filtered by PP filters.

The filter material is completely removed by plasma ashing. The remaining solid material can be analysed for Asbestos fibres.

It's quick, cheap & simple.

info@2x3d.co.uk

#material #machinery #asbestosremoval #coatings #materials #manufacturingprocesses #coating #automotiveindustry #batteries #surface #plastic #cleaning

Adhesive

Bonding. What do you know? What do you need to know? - October 11th 2018

Obviously you need a clean and activated surface before even thinking about anything else! Come and see Diener Electronics Plasma Surface Technology at the number one fair of it's type -

https://lnkd.in/dQK8xeZ

You would be welcome. Please send us your questions so that we can prepare your concise answer prior to arrival.

info@2x3d.co.uk

#medicaldevices

#materials

#chemistry

#surface

#coatings

#savings

#electronics

#howto

#semiconductors

#painting

#adhesives

#contamination

#adhesivebonding

#plasmas

#sealing

#rubber

#plasmatreatment

Do you use ABS? - October 5th 2018

Acrylnitril-Butadien-Styrol-Copolymer is an impact resistant thermoplastic resin. Many consumer goods and housings are produced out of ABS because its good mechanical properties, easy processability and it's low price. In order to facilitate post moulding processes, Plasma treatments can be applied to increase the adhesion of Inks, Coatings, Paints and Adhesives.

#medicaldevices

#materials

#chemistry

#tpe

#semiconductors

#surface

#plasma

#consumergoods Plasma simplifies process info@2x3d.co.uk www.2x3d.co.uk